Revoria Press EC2100

Nouvelle génération de presses numérique 4 et 5 couleurs de milieu de gamme

Nouvelle génération presses numérique

Faites passer vos impressions à la vitesse supérieure

Les presses numériques Revoria Press EC2100 et EC2100S intègrent une série de technologies avancées, au service d’une qualité et de performances révolutionnaires, ainsi que d’une incroyable polyvalence en matière d’applications. La Revoria EC2100S propose également une cinquième couleur pour l’impression de couleurs plus étendues et d’effets spéciaux, pour vous aider à vous démarquer sur un marché chaque fois plus exigeant.

jusqu'à

100ppm

A4 CMJN

jusqu'à

5 couleurs

52 à 400 g

poids des médias

Maximum

330 x 1300 mm

de format de support

Bienvenue a la 5UPER COULEUR de Revoria : deux nouvelles presses numérique de milieu de gamme qui associent une cinquième couleur à des performances d’exception pour vous aider à vous démarquer sur un marché chaque fois plus exigeant.

Découvrir plusColour Beyond Limits

Discover how colour embellishments can transform print into a high-impact marketing tool that drives attention, elevates brand value, and boosts ROI.

Presse numérique de milieu de gamme de pointe aux performances et capacités couleur avancées

Les Revoria EC2100 et EC2100S vous offrent la nouvelle génération de performances et les avantages de l’impression cinq couleurs, pour vous aider à différencier votre entreprise.

Une qualité d’impression exceptionnelle

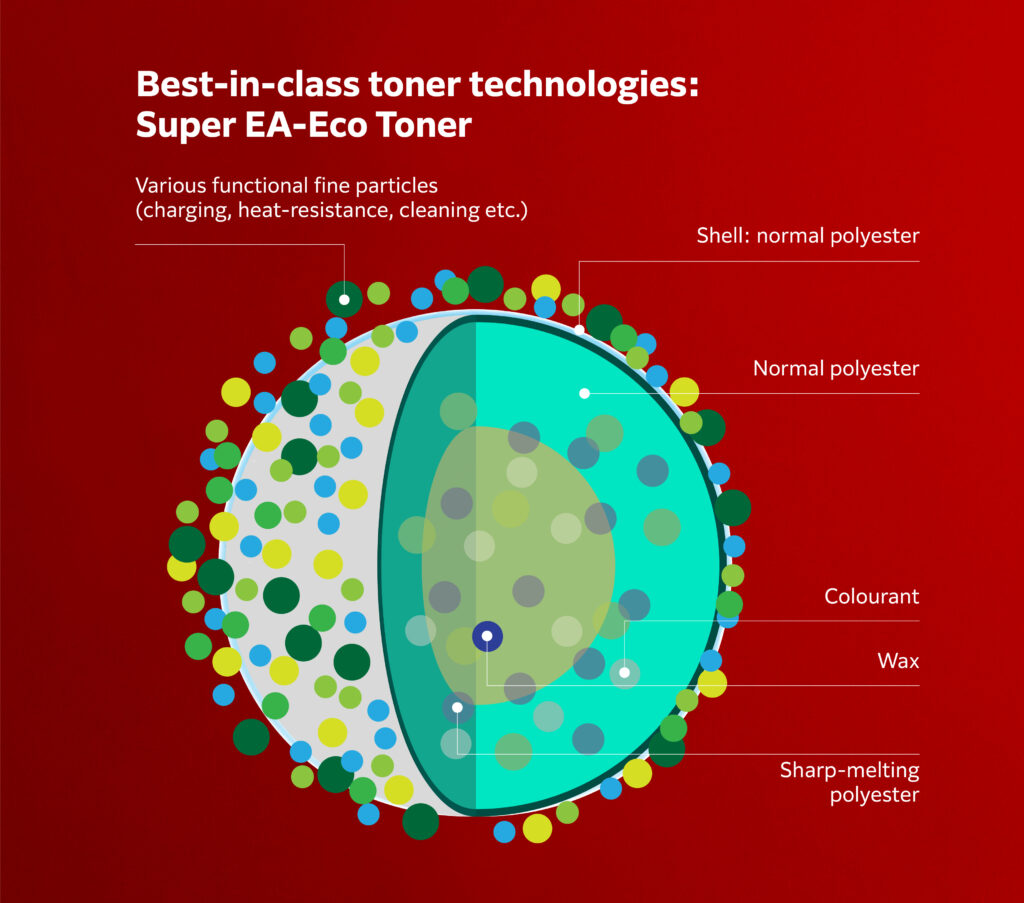

Toner Super EA-Eco

Le toner Super EA-Eco, dont les particules sont actuellement les plus petites du secteur et dont la forme a été standardisée, permet de reproduire des caractères détaillés et des lignes fines d’une grande netteté.

De plus, les dégradés, les demi-tons et les tons moyens sont reproduits de manière plus fluide et les formes de points de manière plus fidèle, pour une qualité d’impression exceptionnelle.

Tête

Les Revoria Press EC2100 et EC2100S bénéficient d’une tête d’impression LED haute résolution, qui produit un imprimé d’une remarquable définition :

Tête d’impression LED 2 400 x 2 400 ppp

Profitez de résultats haute résolution, pour des lignes et des images nettes, et d’une impression haute définition.

Gain de place et économie d’énergie

La taille de la tête d’impression LED a été ramenée à 1/12e de la taille de la génération précédente (VCSEL-ROS) utilisée auparavant. L’absence de moteur permet de limiter la consommation d’énergie, de ne produire aucun bruit et d’obtenir une reproduction d’image d’une stabilité inégalée.

Qualité d’image exceptionnelle

Afin d’obtenir la qualité d’image élevée attendue des imprimantes de production, nous avons perfectionné et amélioré les unités de développement et de transfert, ainsi que leurs technologies associées.

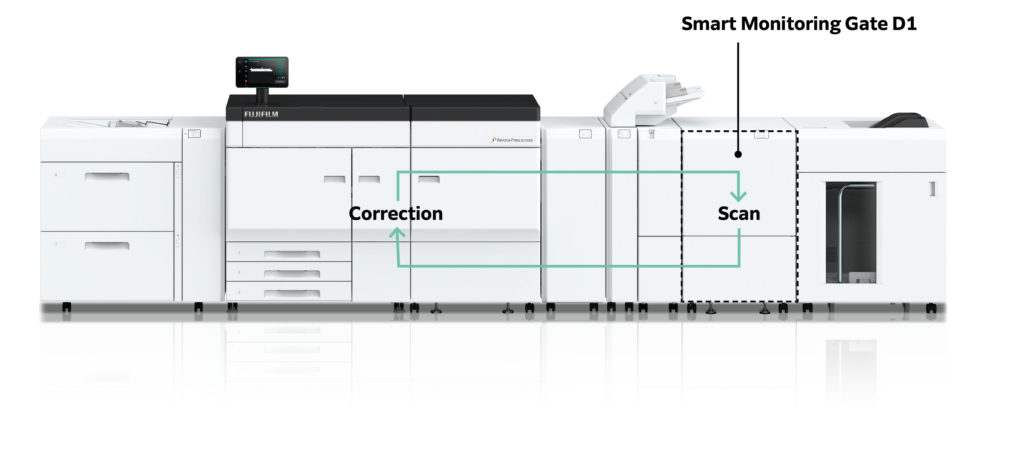

Optimisation des impressions intelligentes en temps réel

Les Revoria Press EC2100 et EC2100S intègrent une Smart Monitoring Gate D1 en option qui contrôle la couleur et le repérage avant/arrière des travaux d’impression lors de l’impression.

Optimisation de la productivité et du temps de fonctionnement

Vitesse d’impression maximale de 100 ppm pour chaque gramm

Les Revoria Press EC2100 et EC2100S offrent une cadence d’impression allant jusqu’à 100 ppm pour le format A4 CMJN et jusqu’à 55 ppm pour le format A3 CMJN. Cette vitesse concerne

Nouvelle courroie de transfert

L’utilisation d’un nouveau système de courroie de transfert (BTB) plutôt que du rouleau de transfert (BTR) conventionnel garantit un transport plus stable et dès lors plus fiable du papier, et permet d’imprimer un plus large éventail d’applications. Le nouveau système adapte automatiquement la pression au point de contact en fonction de l’épaisseur du papier, améliorant le transfert du toner. Nouveauté des Revoria EC2100 et EC2100S, ce mécanisme produit une qualité d’impression supérieure, en particulier sur le papier gaufré.

Mécanisme de transfert de charge au bord d’attaque

Fujifilm a doté ses EC2100 et EC2100S d’un volant à excentrique qui fournit une force d’inertie au rouleau de la courroie de transfert pour un entraînement stable. La rotation de ce volant et la force d’inertie suppriment les vibrations de la courroie de transfert, permettant un transfert stable des supports même pour le papier épais.

Nouvelle technologie de développeur

La détérioration du développeur est l’une des raisons de l’instabilité éventuelle de la qualité d’impression au fil du temps. Dans les modules conventionnels de marquage horizontal, il peut arriver qu’une partie du support de développement parvienne à nouveau au rouleau de développement, affectant potentiellement la qualité d’impression.

Dans le nouveau système de développement vertical utilisé sur les EC2100 et EC2100S, l’état du matériau de développement est rafraîchi avant qu’il ne soit réintroduit dans le rouleau de développement. L’ensemble du développeur utilisé est ainsi toujours parfaitement frais et conditionné, raison pour laquelle les Revoria EC2100 et EC2100S offrent une si belle impression au fil du temps, et en particulier sur les papiers épais, rugueux et gaufrés.

Capacités de pointe de gestion du papier

Les Revoria Press EC2100 et EC2100S sont équipées de plusieurs technologies de marquage avancées qui améliorent les capacités de traitement du papier, étendent les possibilités d’impression et augmentent le temps

Papier gaufré, papier rugueux, papier épais

La toute nouvelle courroie monocouche avancée (A-SLB), le mécanisme de commutation de la charge de transfert secondaire et la technologie de stabilisation de l’état du toner ont permis d’améliorer considérablement le transfert du toner sur papier gaufré et épais.

Papier normal, papier rugueux

Le perfectionnement des technologies de formation et de transfert d’images nous a permis d’améliorer la qualité d’impression sur papier normal et papier rugueux.

Nous avons par ailleurs développé une technologie de stabilisation du champ électrique de transfert optimale pour chaque type de papier. Les densités d’impression sont ainsi plus homogènes.

Papier épais, enveloppes

Deux nouvelles technologies de transfert papier assurent des capacités inédites de traitement du papier épais et des enveloppes :

• Le nouveau mécanisme de commutation de la charge de transfert secondaire modifie la pression de maintien du papier selon l’épaisseur de celui-ci.

• Le nouveau mécanisme variable du couple de transfert stabilise l’alimentation papier

Papier fin

L’utilisation d’un dispositif de transfert de type bande, et non de type rouleau, renforce la polyvalence des impressions sur papier fin.

Cartes postales

Le fait de bloquer la zone en dehors du chemin papier par un volet améliore l’adsorption du papier et la stabilité de la manipulation des cartes postales dans l’imprimante.

Autres technologies de gestion du papier

Éliminateur d’électricité statique

Le module d’élimination statique D1, disponible en option, supprime efficacement l’électricité statique sur de nombreux supports, y compris les films monocouches, le papier synthétique, le papier résistant à l’eau et le papier d’affichage.

La charge est réglable de 0 à 99 et peut également être ajustée lorsque la presse est en marche.

Correction du tuilage

Un module de détuilage compact et intégré évalue et corrige automatiquement le tuilage lié au type de papier ou à la densité de l’image, en temps réel et pour chaque page. Produisez des impressions de haute qualité avec une circulation stable du papier et sans gondolage.

Le module d’interface de détuilage D1, disponible en option, propose d’autres étapes très simples permettant d’ajuster le tuilage. Un véritable gain de temps si vous changez souvent de support d’impression.

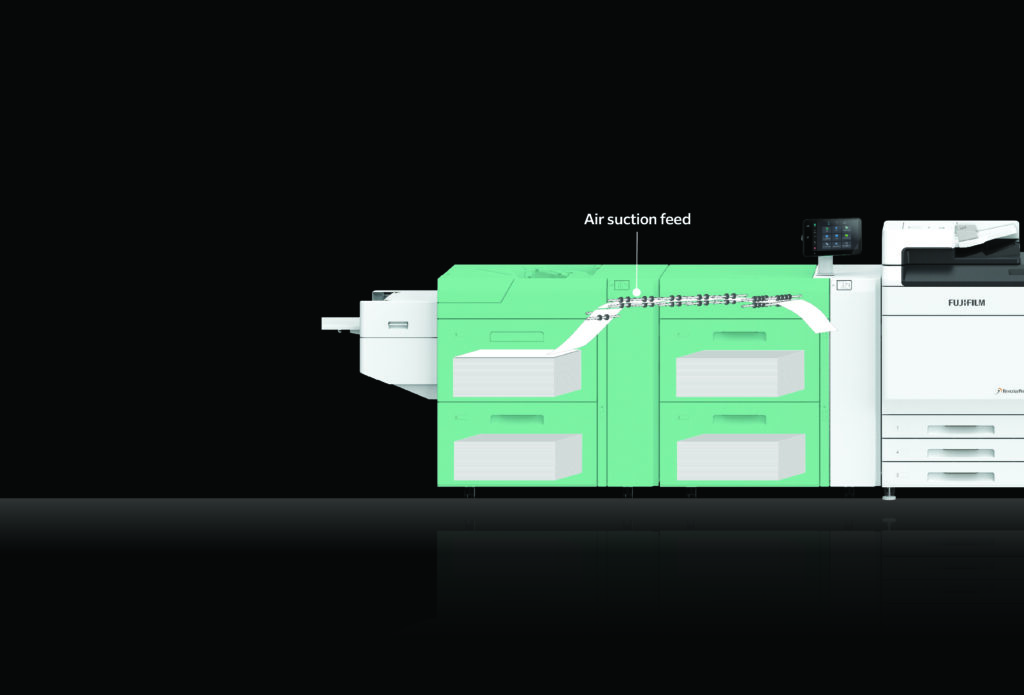

Alimentation par aspiration d’air

L’alimentation par aspiration d’air, disponible en option, permet d’améliorer les performances d’alimentation de divers types de papier : papier recouvert de poussière, papier préimprimé utilisant de la poudre, papier présentant une texture irrégulière et papier couché. Plusieurs types de papier, qu’il s’agisse de grammages légers ou épais, de petits formats ou de feuilles pour bannières, bénéficient d’une alimentation stable à grande

La tête mobile soulève le papier efficacement à l’aide d'une petite quantité d’air, afin de séparer et de distribuer chaque feuille correctement. Cette tête active évite les frottements sur la surface du papier, phénomène pouvant s’avérer

Étapes vers une impression plus durable

Les Revoria Press EC2100 et EC2100S disposent d’un certain nombre de fonctions d’économie d’énergie, par exemple la tête d’impression LED et le toner Super EA-Eco, afin de réduire la consommation d’énergie lors de l’impression.

Ces imprimantes ont également obtenu la certification de désencrage supérieure de la part du célèbre organisme industriel INGEDE. Cette certification atteste que le toner peut être facilement retiré de chaque impression réalisée par ces presses. Les documents imprimés sont ainsi plus facilement recyclables, augmentant davantage le caractère durable des presses.

Les impressions réalisées sur les Revoria Press EC2100 et EC2100S ont été testées selon la méthode 11 de l’INGEDE et évaluées conformément à « l’évaluation des possibilités de recyclage des produits imprimés - score de désencrage » (EPRC 2017).

Elles ont obtenu un score total de 100/100 points.

Format compact

Les Revoria Press EC2100 et EC2100S sont dotées d’un tout nouveau « système de développement vertical » et d’une tête d’impression LED ultra compacte. Résultat : une presse 5 couleurs d’une taille identique à celle du modèle 4 couleurs qui l’a précédée, la Revoria Press EC1100.

Demander une démonstration

Découvrez ce que la Revoria EC2100 peut faire pour votre entreprise

Request a demo – Revoria Press EC2100

Merci pour votre demande, quelqu'un vous contactera bientôt.

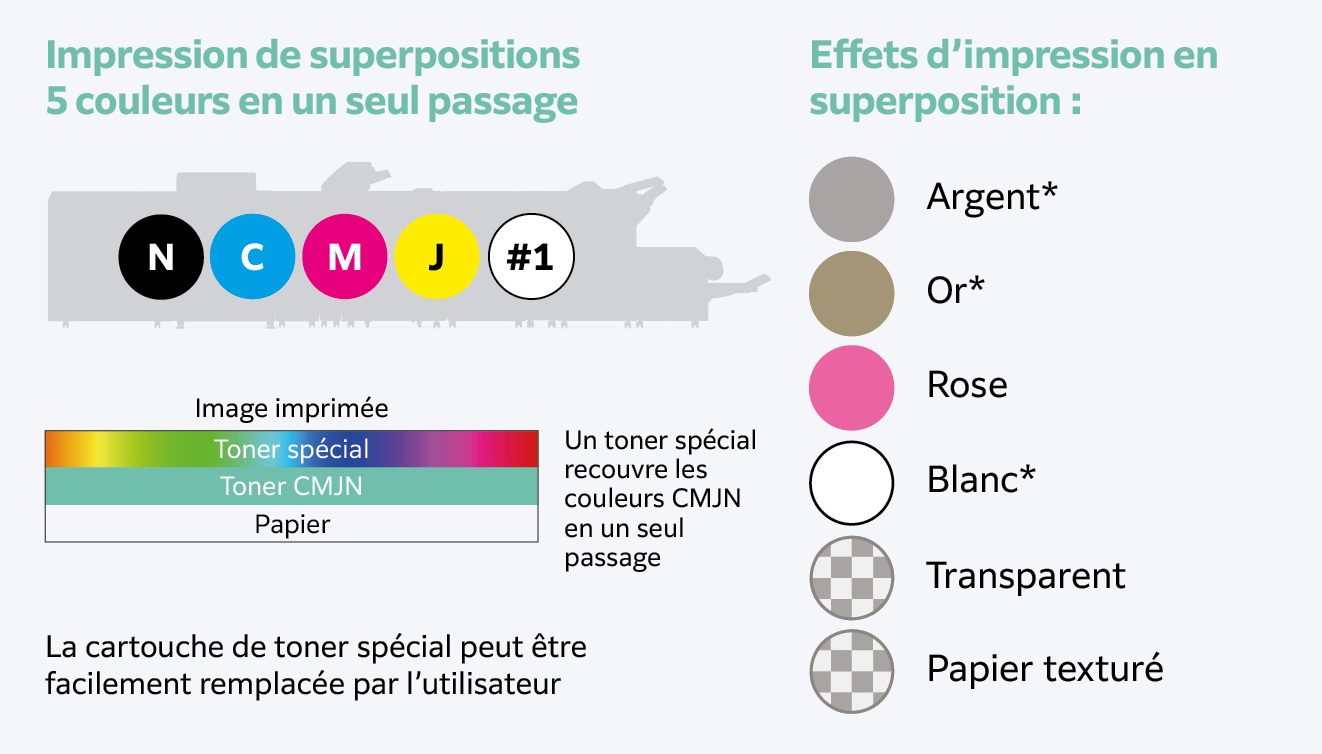

Différenciez votre activité grâce à l’impression à valeur ajoutée

La Revoria EC2100S vous permet de produire des impressions de qualité supérieure à valeur ajoutée en utilisant des toners spéciaux comme cinquième couleur, en plus du CMJN. Ces toners spéciaux peuvent être imprimés en superposition du CMJN et peuvent tous être remplacés facilement et rapidement par l’utilisateur.

Valeur ajoutée du toner rose

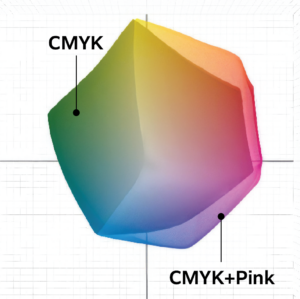

Un espace colorimétrique étendu

Les toners CMJN + rose étendent la gamme de couleurs des tons rouges et bleus, permettant d’imprimer des couleurs plus vives. Il est notamment possible de reproduire des bleus-violets et des oranges vifs impossibles à obtenir avec le mode CMJN seul. Cela signifie également que vos impressions refléteront plus fidèlement les couleurs du système RVB.

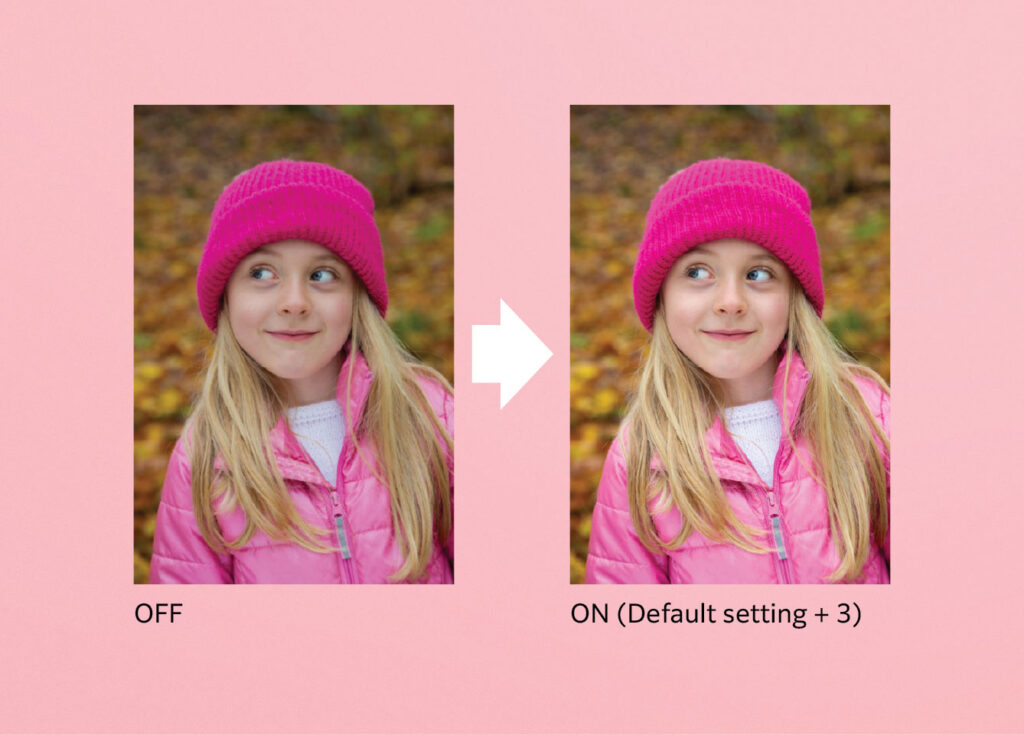

De plus, l’activation de la fonction « Utiliser un toner spécial dans la simulation RVB » permet d’imprimer les tons de rose, d’orange et de violet de manière plus vive et plus éclatante, se rapprochant ainsi des couleurs affichées en RVB sur un moniteur.

Amélioration des tons chair

L’ajout de toner rose permet de réduire sensiblement le grain des tons chair, et ce, quelle que soit la tonalité. Par ailleurs, une fonction unique du Revoria Flow, « Éclaircir à l’aide du toner rose », permet d’imprimer les tons chair de manière plus vive et plus esthétique.

Valeur ajoutée du toner transparent

Utilisez le toner transparent pour faire ressortir certaines zones d’impression avec un effet vernis parfaitement aligné, afin d’ajouter une dimension supplémentaire à vos impressions créatives et personnalisées. Il peut aussi ajouter une touche de luxe en apportant une indéniable finesse aux motifs et aux arrière-plans, et illuminer les images imprimées en CMJN.

Le toner transparent permet de créer des ennoblissements, tels que des motifs brillants ou texturés, ou encore des filigranes et des motifs en arrière-plan pour rendre les documents plus difficiles à copier. Il peut également s’intégrer au système CMJN afin d’ajouter de la brillance à vos impressions (aspect plus lisse) ainsi qu’un effet de type

En savoir plus

Trouvez plus de détails et de spécifications clés dans la brochure produit Revoria EC2100, disponible en téléchargement dès maintenant.

Télécharger la brochureMerci pour votre demande, quelqu'un vous contactera bientôt.