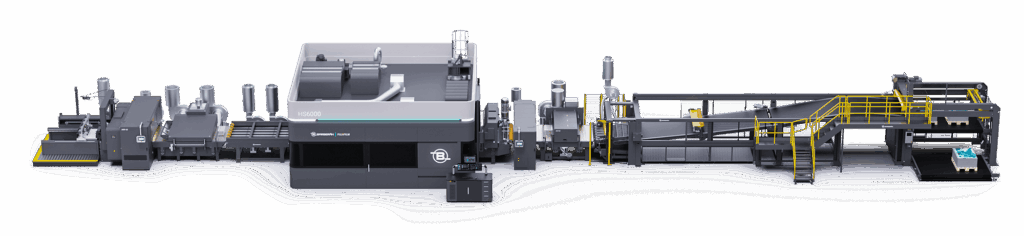

Acuity Aristo

Next generation, single pass industrial press for high volume display graphics

The future of high volume display graphic production

Unrivalled, industrial modularity to fit your business needs

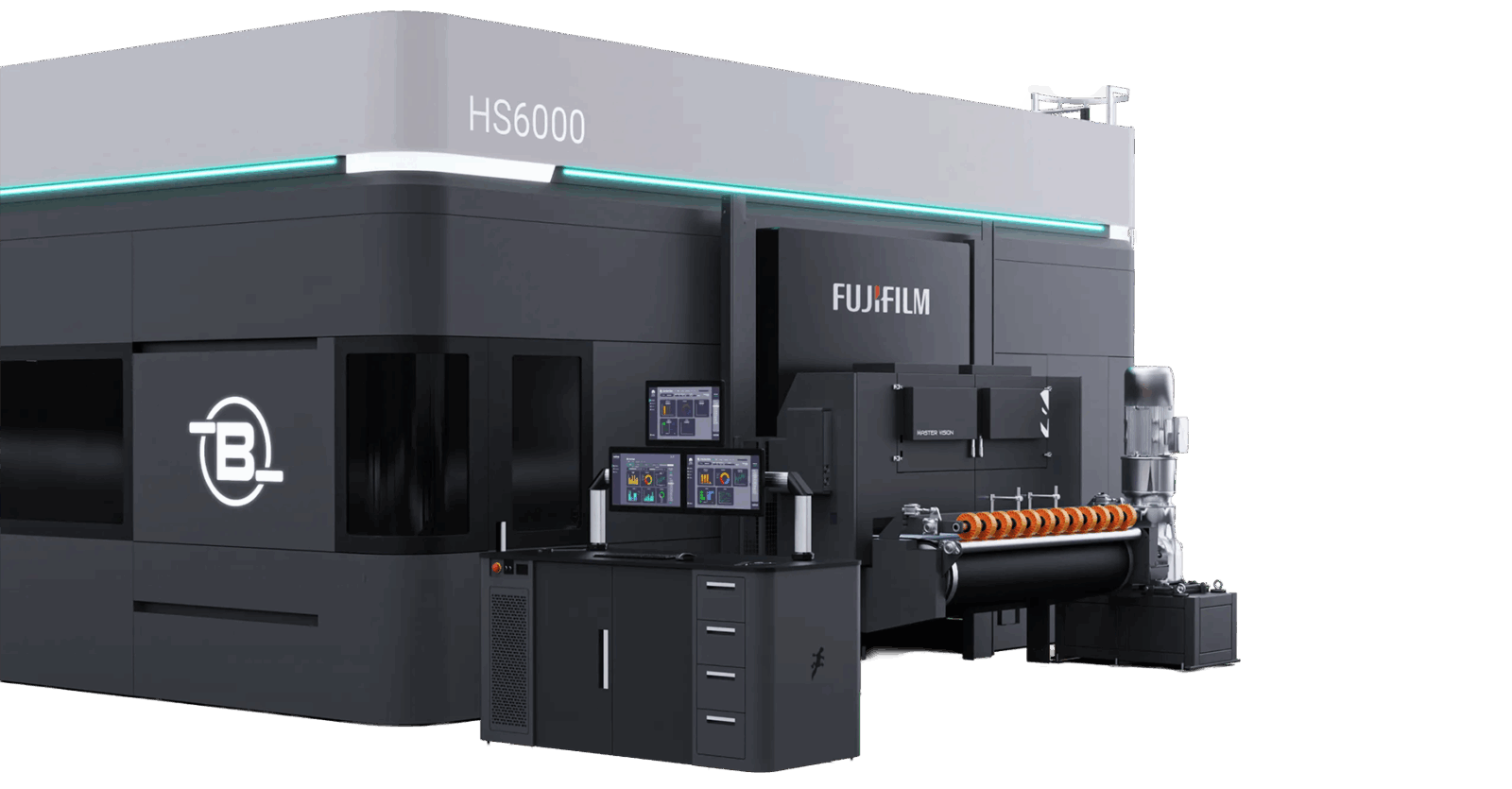

Developed through a collaboration between Barberan and Fujifilm, it combines industrial precision engineering with advanced ink chemistry to deliver outstanding print at scale.

Fino a

2926 sheets

per hour

Fino a

600 dpi

risoluzione di stampa

Fino a

1.61 m x 3m

print size

Precision inkjet engineering…

- Experts in industrial print system design and precision manufacturing

- Complete design and fabrication, delivering machines tailored to customer needs

- Built in Europe with robustness, longevity, and future-proof engineering

+

Ink science…

- Expert inkjet ink chemistry innvation and manufacturing

- Ground-up formulation for advanced performance and robustness

- Rigorous quality control for flawless, consistent supply

A complete tailor-made solution for display graphics

Acuity Aristo is fully modular, designed to be configured for your specific production goals. The series includes two print units, ink set options, and an extensive range of powerful automation and finishing modules.

1. Acuity Aristo HS3000 with manual feeding

Ideal for fast turnaround of shorter runs and with a max print width of 1610 x 3000mm and unlimited material length.

- Manual feeding

- OPV applicator + UV dryer

- Alignment table

- Print system (with/without enclosure)

- Manual stacking

- Productivity 710 sheets per hour

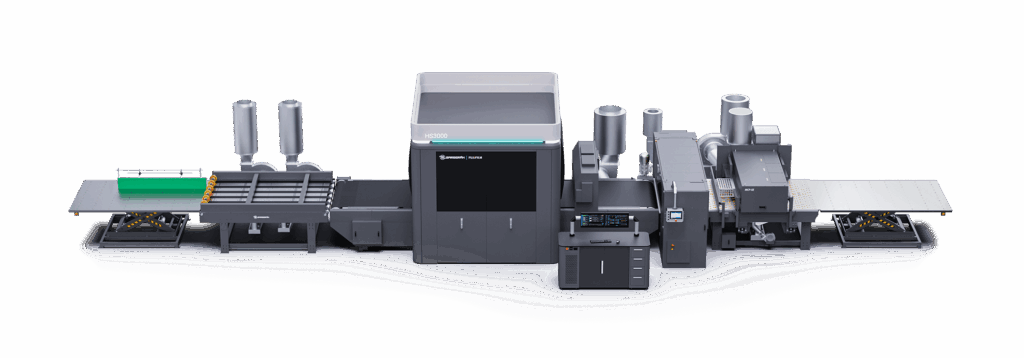

2. Acuity Aristo HS3000 with auto pallet-to-pallet feeding

Ideal for fast turnaround of longer length runs with pallet-to pallet automation and max material size of 1610 x 3000mm.

- Pallet-to-pallet top feeder

- OPV applicator + UV dryer

- Alignmenttable

- Print system (with/without enclosure)

- Pallet-to-pallet top stacker

- Productivity 1224 sheets per hour

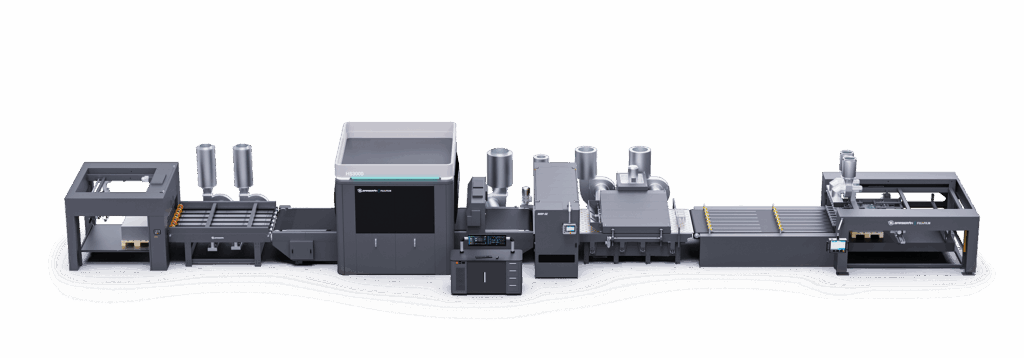

3. Acuity Aristo HS6000 with continuous rigid media feed

Ideal for fast turnaround of longer length runs with pallet-to pallet automation and max print size of 1610 x 3000mm.

- Bottom feeder

- AQ primer

- Print system (with/without enclosure)

- Inspection system

- Pallet-to-pallet top stacker

- Productivity 1960 sheets per hour

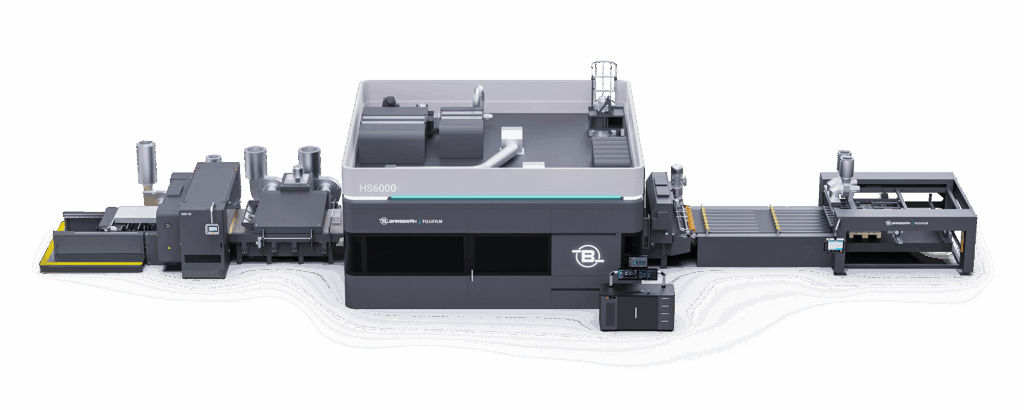

4. Acuity Aristo HS6000 for ultimate production capability

The Acuity Aristo HS6000 includes top feed, pallet-to-pallet automation and bottom feed, continuous production with max print size up to 1610 x 3000mm.

Experience 80m/min feed rates on bottom fed material and a full host of features for high speed, continuous production.

- Hybrid feeding/stacking

- UV/AQ primer

- Alignment table

- Print system (with enclosure)

- Inspection system

- OPV applicator + UV dryer

- Productivity 2926 sheets per hour

Request a demo – Acuity Aristo

Grazie per la tua richiesta, qualcuno ti contatterà presto.

Request a print sample – Acuity Aristo

Grazie per la tua richiesta, qualcuno ti contatterà presto.

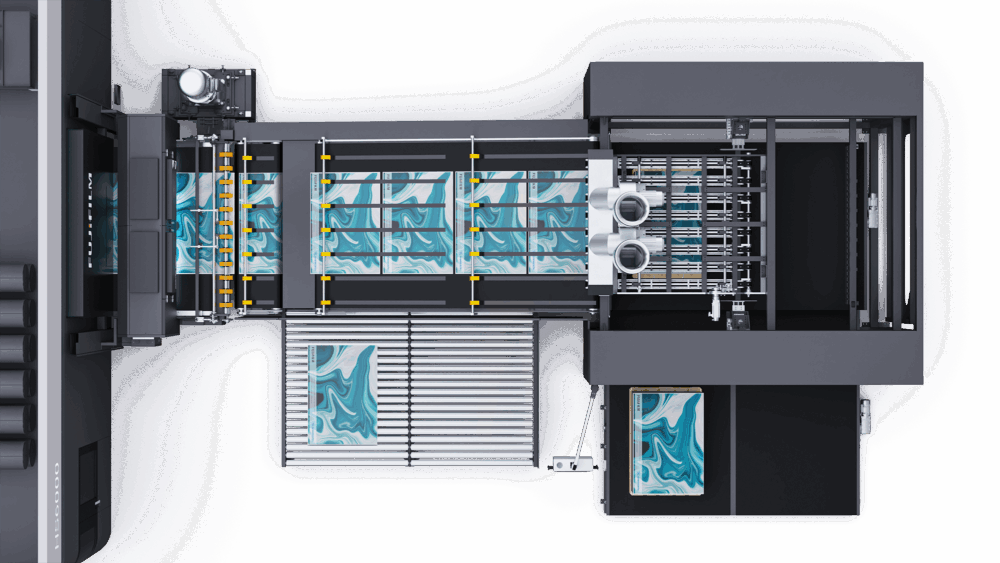

Unrivalled media flexibility to fit your business needs

Print your way

The Acuity Aristo series provides unrivalled versatility with the ability to handle a wider range of typical sign and display media than previously possible with other presses. This is due to a wide range of feeder options including a unique hybrid feed system allowing you to seamlessly switch between top and bottom feeding, meaning you can handle all your display graphic needs in a single solution.

Market leading quality at stunning speeds

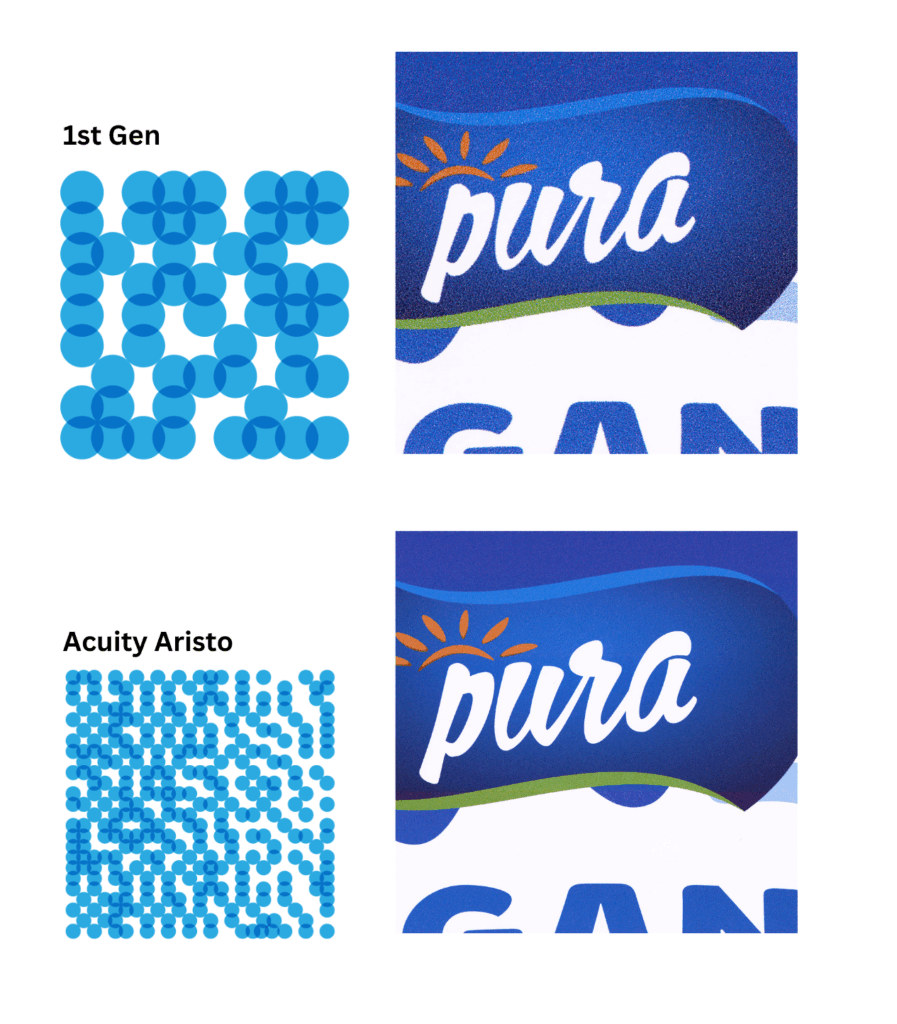

Printhead Performance

600 dpi resolution

Even at top speeds with an optional second channel

2x better than 1st Gen

5 pl drop size

Achieve 3 point text and soft gradient effects with ease

3x smaller drop than 1st Gen

Improve your workflow

The Acuity Aristo series is full of features designed to make operation as efficient as possible and your life easier. Maximising uptime and output while minimising ink use, energy and maintenance time for you to get through print jobs faster than ever for less.

Primer-free advantage

When you are producing a wide range of print jobs every day, you need production flexibility. Acuity Aristo can print on many materials directly without primer. This reduces consumables, lowers energy use, and speeds up turnaround, cutting operating costs and improving efficiency.

Fully-automated production

High-speed single pass printing demands equally advanced automation to sustain throughput and minimise downtime. Acuity Aristo has multiple automation options, and the fully modular design concept means it can be configured for your needs today and scaled for tomorrow.

Dedicated ink chemistry

Acuity Aristo LED curing inks are developed for the performance demands of high-productivity single-pass printing. With an exceptional gamut for vibrant, colour-accurate output, the high-functionality chemistry enables many materials to be printed without primer.

A versatile general ink set covers the full spectrum of display materials, while specialist sets provide enhanced performance for focused production. Varnish supports a wide range of finishing requirements.

Scopri di più

Learn more about the Acuity Aristo and how it can transform your print production by downloading our product brochure.

Scarica la brochureGrazie per la tua richiesta, qualcuno ti contatterà presto.