Leia o artigo

Tempo de leitura 6 minutos

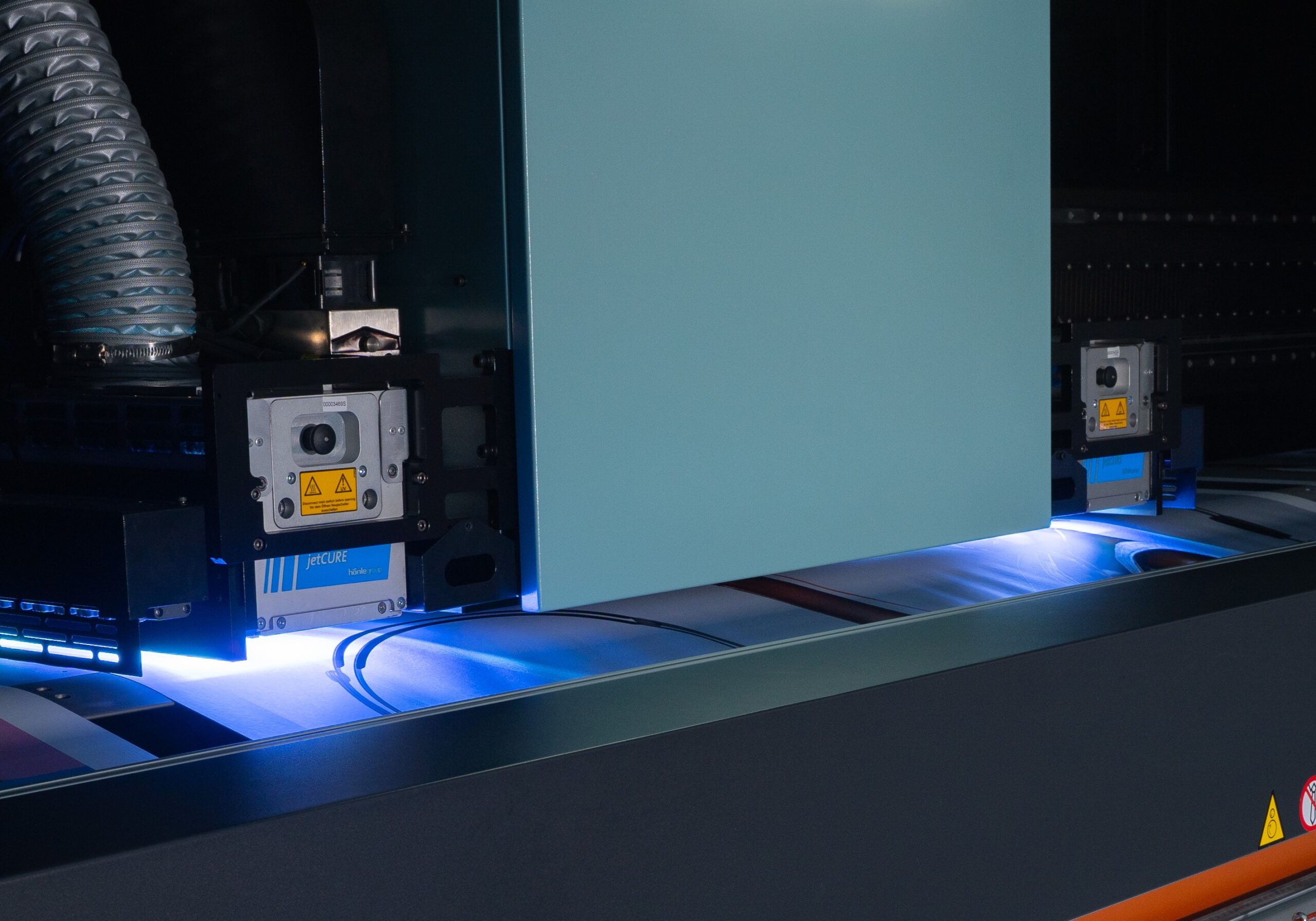

LED UV curing technology is energy efficient, environmentally friendly, and extremely well suited to the production of a huge range of applications. It’s a massive area of R&D focus for Fujifilm and it is, quite rightly, seen as a key “technology of the future.” So far, so uncontroversial.

And yet, none of that means to say that conventional UV curing has – or will – become a “thing of the past”. Despite the obvious cost and environmental advantages of LED technology, there is no reason to believe that it will replace conventional UV altogether. It won’t. In fact, both technologies will continue to play valuable roles in the future of wide format print long into the future, and where conventional UV is the more appropriate solution, we at Fujifilm will continue to offer customers that option. This is something we’ve clearly demonstrated with the launch of the new Acuity Ultra R2 – which is available in either LED UV or conventional UV curing formats.

Pros and cons

LED UV does, of course, use far less energy than its conventional alternative. As LED UV lamps have a significantly lower level of applied voltage, LEDs have a lower radiance than conventional UV lamps. LEDs emit light in the visible part of the spectrum from 400 nm to 700 nm or in the near infrared (700 nm and 2000 nm), so only part of the spectral energy they emit is UV light. Because they use a fraction of the energy of conventional UV lamps, they don’t need to warm up or cool down, so they are immediately ready for use and don’t use energy unless they are operating.

Furthermore, LED UV lamp lifetimes are much longer than those of conventional UV lamps (approximately 10,000 working hours compared to 1000+ working hours). As a result, one of the main selling points of LED UV for customers is the fact that it is more environmentally friendly and that costs are lower. There is only one real downside: the lack of safe cure and adhesion of high ink deposits at speed, which for some printers is a substantial issue.

Understanding the relevant regulation

Another common reason cited for the inevitable decline of conventional UV is government regulation. But here, many of the regulations concerning conventional UV are widely misunderstood. The European Union’s Restriction on Hazardous Substances II (RoHS II) regulation bans the use of heavy metals, including lead, mercury and cadmium. As a result, domestic light bulbs that use conventional UV can no longer be purchased, having been replaced by LED UV. For this reason, many assume that conventional UV for business use is on a similar path to regulatory oblivion.

However, this regulation does not apply to larger printing equipment, which is typically classified as ‘large-scale stationary industrial tools” (LSSITs), so the UV dryer modules manufactured for them are exempt from the RoHs II directive. Through the development of UV technology and compliance with the manufacturer’s information on safe disposal, the use of medium-pressure UV lamps containing mercury within the printing industry is deemed safe. As a result, mercury is still widely used throughout the industry and there is no indication that this is likely to change.

Counting costs

The operating costs of LED UV are certainly lower than the costs involved with a conventional UV machine, where increased energy and consumables usage needs to be factored in. But if the extra speed and increased adhesion and block resistance of conventional UV allows a print business to produce more work, the additional business can more than cover all these costs, as well as funding responsible waste management systems to minimise environmental impact.

Heat and speed

Another common belief is that conventional UV cannot be used on heat-sensitive materials, but Fujifilm’s Acuity Ultra R2, for example, features a unique water-cooled vacuum table that allows rapid UV curing on a huge range of thin, heat-sensitive materials. The main benefit of conventional UV that cannot be matched by LED UV is the speed at which it is able to print. Depending on the user, this one benefit can outweigh many of the negatives, meaning that it’s often the option that makes the most sense for many businesses. As conventional UV undoubtedly dominates the market in terms of productivity, it remains the obvious option for printers producing high volumes with rapid turnaround times.

Conventional UV is best for high production, fast-turnaround print. LED UV offers environmental, cost, and energy saving benefits when speed is not as crucial.

Kevin Rhodes | Marketing Manager, Fujifilm WFIJ Systems

The choice is yours

LED UV, of course, has an extremely valuable role to play in the future of wide format print– and we’re very proud at Fujifilm of our extensive range of LED UV curing printers. But it is not a complete replacement for conventional UV. There is still very much a need for both types of technology, depending on the customer’s requirements. The two exist in tandem and will continue to do so. Conventional UV is best for high production, fast-turnaround print, while LED UV offers a multitude of environmental, cost, and energy saving benefits when speed is not as crucial. Until LED can match conventional UV’s performance, specifically its speed and depth of cure, it is unlikely to be a wholesale replacement for conventional UV.

Ultimately, it’s up to the customer to decide on the most appropriate solution for their business, and we will continue to offer them that choice.