Revoria E1 Series

Advanced, high quality monochrome print production

Enhanced productivity on demand

A versatile and advanced range of printers designed to produce the highest quality monochrome print

The Revoria E1 Series is able to produce the highest quality monochrome print consistently and reliably at speeds of up to 136ppm. Capable of continuous operation, and with a wide variety of feeding and finishing options, it will deliver a huge range of high quality monochrome finished print.

Tot wel

136

pagina's/minuut

Uitstekend

2400 x 2400 dpi

print quality

Tot wel

350g

substrates

Een drukproef aanvragen

See the quality you could achieve with the Revoria E1 Series

Request a sample – Revoria E1 Series

Thank you for your enquiry, someone will be in contact soon.

Flexible feeding and finishing options

Supported feeding and finishing options include the insertion of a cover, three-sided trim, and saddle stapled booklets with a square back

Uw volledige ondersteuningspakket

Ons team van deskundigen neemt alle tijd om uw unieke eisen en doelen voor de ondersteuning van uw print-on-demandservice te doorgronden.

Download voor meer informatieThank you for your enquiry, someone will be in contact soon.

A new range of Revoria digital presses from Fujifilm

Revoria is geen gewoon assortiment. Het is afkomstig van Fujifilm – een bedrijf met een diepgaande kennis van zowel offset- als digitaal drukwerk, een lange geschiedenis in het leveren van toonaangevende, duurzame printoplossingen en een cultuur van eerlijke en open langdurige partnerschappen. Met een ambitieus plan om nieuwe digitale tonerpersen als onderdeel van dit assortiment te lanceren, is dit nog maar het begin.

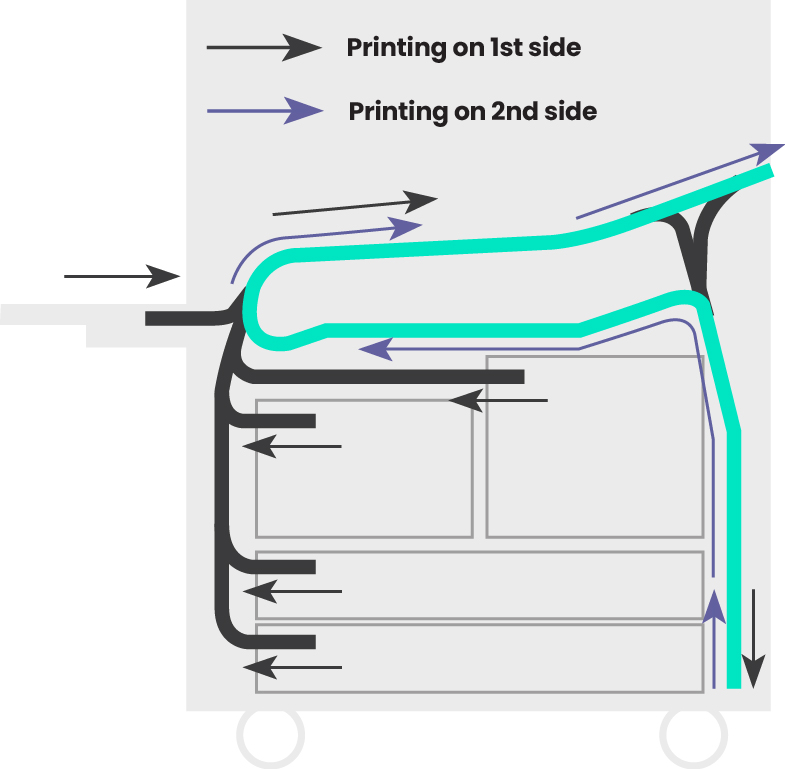

Stable and reliable production

Stable paper transport

Wide turning angles in the paper path mean that the paper transport is fast and stable. In addition, for 2 sided printing, a vertical paper inversion mechanism reduces curves in the paper path to minimise paper jams. Finally, as the EA-Eco LGK toner fuses at lower temperatures, less impact is caused by the heat generated by the fused paper on the transfer mechanism, minimising paper transport issues.

Air suction feeder with enhanced paper handling capabilities

The air suction feeder uses a small amount of air to easily separate and deliver each sheet efficiently. This improves the feed performance of many types of paper, for example paper with a lot of dust, pre-printed paper using powder, paper with an uneven texture, and coated paper that is prone to sticking. In addition, a stable feed is achieved at high speeds for various paper weights, from light to heavyweight, and from small sizes to large.

Continuous mass printing

High capacity feeders and stackers make continuous mass printing possible. In addition, cartridge replacement and paper refills can be done while printing is in progress, with a single high capacity toner cartridge yielding up to 71,500 pages.

No more multifeed and mixed blank pages

The multifeed detection sensor monitors the paper flow to prevent the feeding of multiple sheets of paper. If a multifeed is detected, printing is interrupted to prevent the insertion of a blank page.

Superb, high resolution print quality of 2400 x 2400 dpi

The heart of the printer uses Vertical Cavity Surface Emitting Lasers as a light source. They enable printing at an ultra-high resolution of 2400 × 2400 dpi by producing images simultaneously with 32 laser beams.

EA-Eco LGK toner for high image quality

The EA-Eco LGK toner, with extremely small particle sizes of 6.5 microns, allows the reproduction of smooth, fine gradations in photographs, uniform densities and very fine text to be achieved. It also produces easy-to-read printed text with less glare which is also easy on your eyes.

Advanced transfer unit for consistent transport speed

Designed to prevent fluctuations in paper transport speed, the stable drive speed of the transfer belt has been achieved by increasing the roll diameter, along with the automatic adjustment of contact pressure between transfer belt and drum. These measures ensure consistent transfer speeds of all paper types.

Ultra-high precision registration

Image Registration Control Technology (IReCT) precisely measures the position of sheets running at high speeds, and produces real time corrections to the poor registration of printed images or distortion on each sheet to ensure the highest possible quality.

Maintain print quality with easy adjustments

To maintain print quality, easy adjustments can be made with the Simple Image Quality Adjustment (SIQA) process by just printing and scanning the calibration chart. This ensures consistent print quality with properly adjusted print position, perpendicularity, skew and magnification on both the front and back sides.

Edge enhancements improve image quality

Higher image quality has been implemented with ‘Edge Enhancement’ technology that fixes the jaggedness on the edge of thin lines and text outlines, along with ‘Adjust Invert Text/Line Weight’ technology that fixes thickened/blurred text.

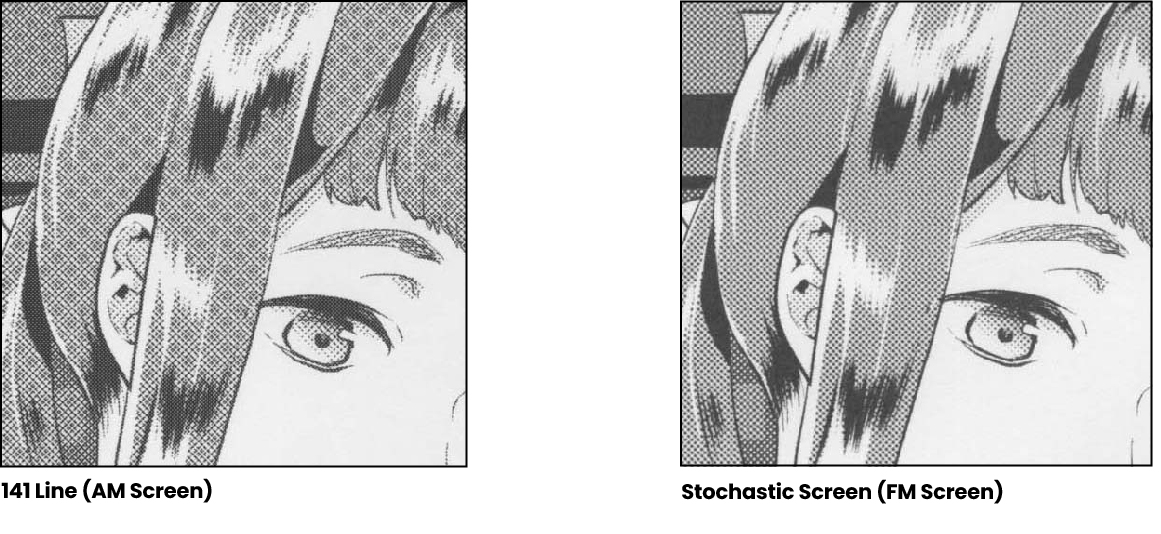

A wider variety of screening choices

Various screen settings, including an FM screen that suppresses moire, are are now available.

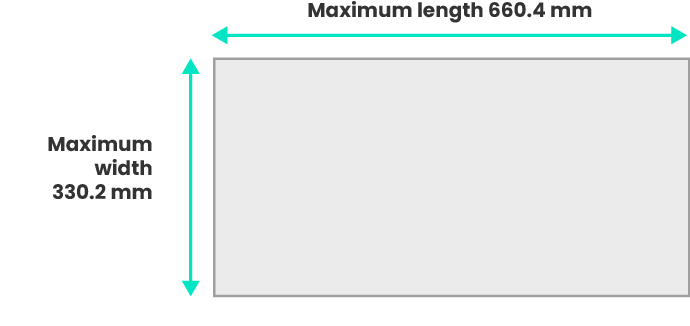

Flexible and versatile media handling

A wide range of paper weights, feeding options and finishing systems ensure the most versatile production.

Media handling capabilities

The Revoria E1 Series can handle a wide range of paper weights from lightweight paper of 52 gsm to heavyweight paper of 350 gsm. The upper limit of heavyweight paper has been extended thanks to the paper path design, and by employing a control mechanism that automatically switches fusing roll pressure between two levels. Fine control has also been achieved to extend the range of supported coated and speciality papers.

Paper sizes ranging from A6 to 330.2 × 488 mm are available. Full bleed printing on SRA3 (320 × 450mm) sheets is also possible to create brochures or leaflets that need to have bleed. In addition, banner printing on long paper of up to 660.4 mm is also available. This means new print applications such as powerful panoramic posters are now possible.

Printing with the correct settings for each media type

Printing with the correct settings for each media type

Up to 100 paper types can be registered with ‘Custom Paper Settings’. This allows configuration settings such as the alignment, fold position and fusing temperature to be set according to the paper being used, to maximise image quality.

Flexible feeding and finishing options

A wide range of feeding and finishing options make it possible to build flexible printing systems that allow many different types of printed brochures to be produced inline. Supported options include cover insertion, three-sided trim, and saddle stapled booklets with square back.

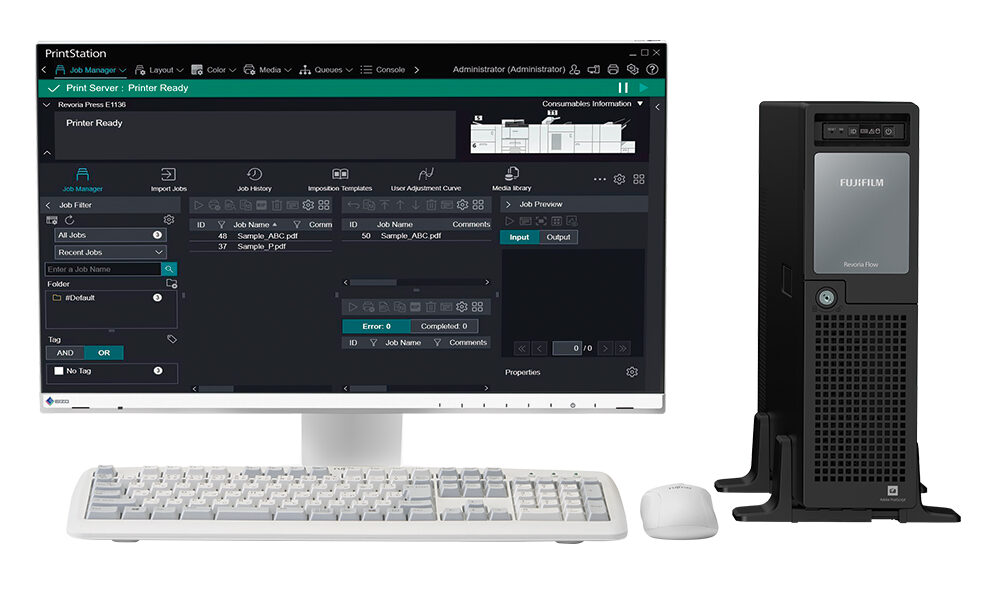

Advanced software

The Revoria E1 Series incorporates advanced software and server infrastructure to support high speed, high quality production.

Image data processing to maximise print engine performance

The advanced print server delivers high speeds and superb image quality by utilising image processing technologies cultivated in the development of colour production printers. High resolution and smooth screen images of 2400 x 2400 dpi are generated on the device with Fujifilm’s unique HQ digital screen technologies.

In addition, our unique intermediate data format streamlines RIP processing. In conventional RIP processing, calculations take a long time due to the large data volumes. However, Fujifilm’s new RIP process algorithms automatically identify objects such as text and images, and process them in the right format, greatly reducing the processing time without degrading image quality.

High speed, large volume printing of variable data

The high speed, large volume printing of personalised documents, including direct mail, bills, statements, etc., is made possible by using industry standard PPML, PDF/VT-1, and PDF/VT-2 languages for variable data printing.

Important print data provided by customers can be protected from data breaches by being securely erased from the print server so that the data cannot be recovered even with data recovery software. In addition, data in the printer can be encrypted or securely erased to prevent unauthorised access.

Support for Adobe® PDF Print Engine

The Adobe® PDF Print Engine directly rips PDF data. Even a PDF file with transparency or layers can be processed, and blur, drop shadow and glow effects can be used with ease.

JDF workflow

JDF, which is a communication and protocol standard in the printing industry, is supported. This means that it is possible to integrate the E1 Series printers into production workflow systems to build a hybrid workflow for both offset and digital printing.

Meer informatie…

Learn more about the Revoria E1 Series by downloading our product brochure

De brochure downloadenThank you for your enquiry, someone will be in contact soon.