Flenex FW

High quality water-washable flexographic plate range

Protect the planet and your profits

A water-washable, high quality flexo plate range that improves productivity while protecting the environment

Flenex FW is a water-washable flexo plate range that provides the ultimate combination of quality, productivity and sustainability, while significantly lowering the cost-in-use compared to solvent plate processing systems.

Up to

40 mins

platemaking time

High quality

200lpi

@ 4,400 dpi

Achieve

1%

flat top dot

Avoid the cost of expensive solvent and thermal processors with Flenex FW, to achieve the lowest flexo plate production costs.

Freshen up your flexo plate making processes with unique benefits

The Flenex FW water-washable plate system does far more than simply eliminate the need for solvents and wicking cloths. It delivers longer runs while producing a consistent 200lpi at 4,400 dpi, 1% process dot structure for superb high quality print, depending on the conditions.

Flexible plate processing options

Fujifilm water-wash processors deliver optimum performance with Flenex FW. The C-Touch MK2 and SB938 plate processing systems offer high performance all-in-one processing for your Flenex water-washable plates, and both feature an extended bath life and efficient plate handling. Available for businesses of all sizes and easy to install, why not bring the whole production process in-house, with the reassurance that Fujifilm is there to help should you need it.

Water Filtration System

- The latest edition to the Fujifilm portfolio is the Water Filtration System, designed specifically to extend the bath life of SB938 and C-Touch MK2 processors, and reduce the amount of water required. Using this system results in a cleaner processor, extending the time between cleaning, allowing maintenance costs to be reduced, and improving environmental performance.

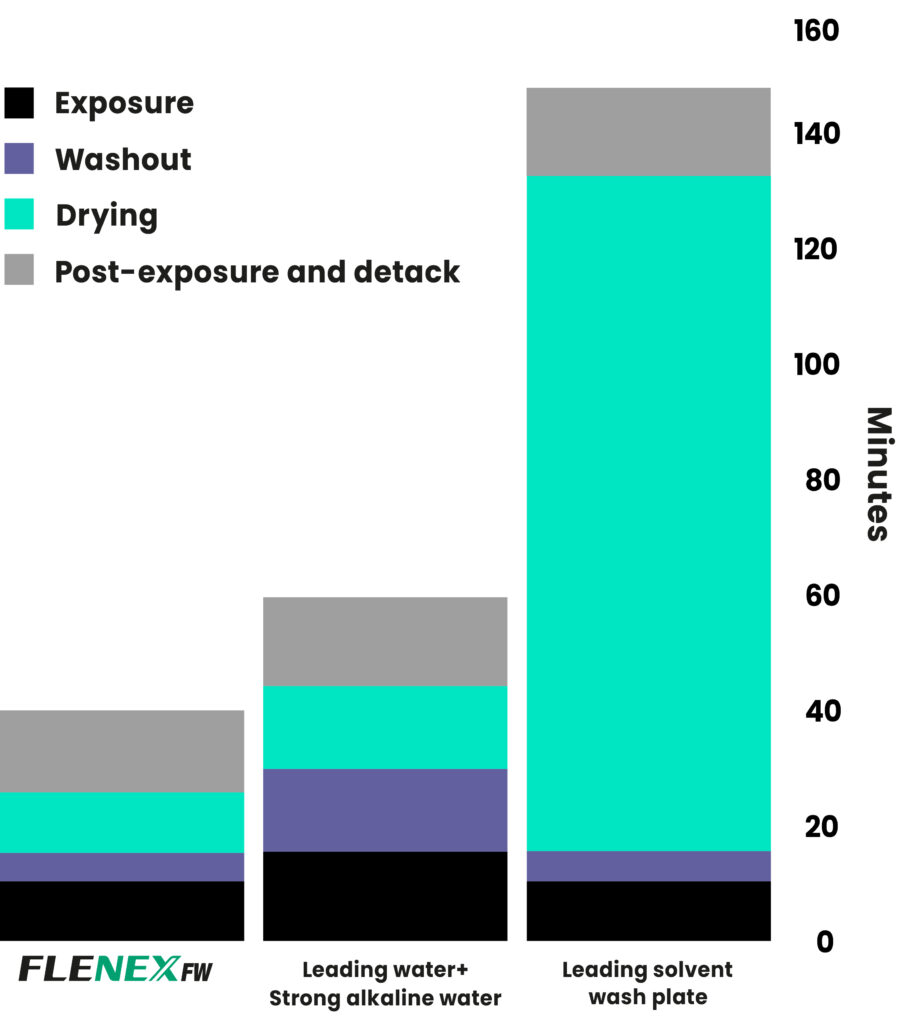

Higher productivity

Flenex FW water-washable plates reduce platemaking processing times to less than 40 minutes, 300% faster than leading solvent systems and 1.5 times faster than current thermal and water-wash technologies. Faster platemaking means more time on press and a dramatic increase in output per shift, freeing you to redeploy labour to more value added activities. Typical benefits include:

- Increase in number of plates produced

- Increase in quality

- Faster job turnaround

- Maximise press time

- Lower labour costs or opportunity to redeploy

- More environmentally friendly plate making

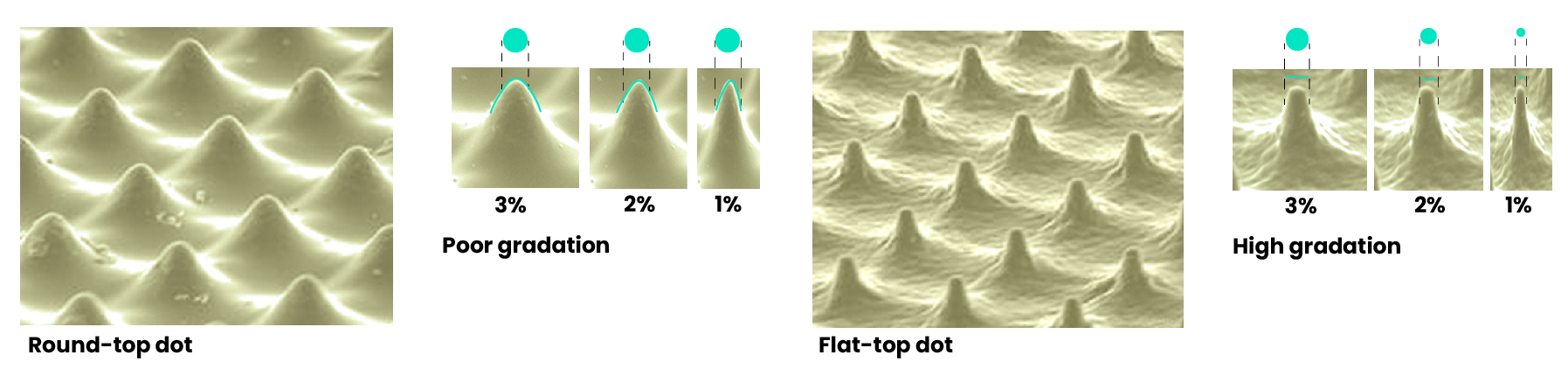

High quality print

The Flenex FW water-washable plate system does far more than simply eliminate the need for solvents and wicking cloths. It delivers longer runs while producing a consistent 200lpi at 4,400 dpi, 1% process dot structure for superb high quality print, depending on the conditions.

Flat top dot structure

The rubber-based compound means a 1% flat top dot can be achieved without complex systems to eliminate oxygen, and results in lower dot gain. In addition, better ink transfer produces noticeably cleaner and brighter print results.

Technology overview

Flenex FW photopolymer plates contain a special rubber-based compound that offers a number of inherent advantages over other elastomeric materials from which most other flexo plates are made. In particular, rubber is not oxygen sensitive, which minimises the effect oxygen in the air has on the dot shape and the complexity of the system to eliminate oxygen from the plate production process. The other advantages of a rubber-based plate material include:

- Reduced dot gain

- Better ink transfer for cleaner, brighter print results

- Faster exposure and washout times

- Much more durable

- Mild washout with water and dishwasher soap

- Reduced plate swell

Sustainability

Less impact on the environment

The use of Flenex FW water-washable flexo printing plates has less impact on the environment, as processing is accomplished with only a mild detergent, and not working with solvents is a huge benefit from a health and safety perspective.

Learn more about sustainabilityThank you for your enquiry, someone will be in contact soon.